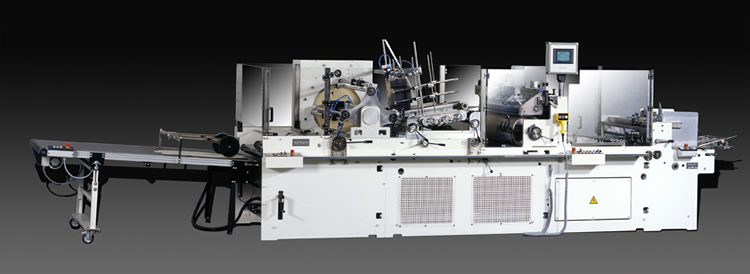

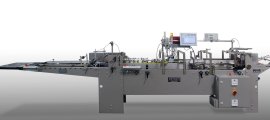

Kohmann Simply Pick

The New Kohmann Simply Pick is able to glue and place precut PVC/PET or any other rigid window material onto carton blanks. Their latest technology enables you to achieve the unparalleled productivity and minimum tolerances.

Specifications

Timed belt feeder

- High performance feeder for card- and corrugated board

- Pre-selection of carton in feed length via touch screen panel

- Feeder with computerized infeed control and speed compensation

The timed belt feeder can work 1 or 2 -up. The infeed length of the blanks is pre-selected via the input panel. The feeder can be switched on or off separately. The controlling and adjusting of the optional suction air control of the stack lifting system is carried out by means of the SPS control unit of the machine and is programmed via the central input unit. Universal adjustment possibilities offer major flexibility and guarantees high performance at all times.

Chain Transport Station

- Transport chains running in closed plastic guides

- Upper guiding system mounted at a central lift off device

- Very robust design

- Jam control of the blanks by means of photocell

Two transport chains align the blanks coming from the feeder accurately for working in one or dual lane operation.

Suction belt transport

- Suction belts split in the middle for optimal blank control

- 2 independent working suction tables

- Suction table drop down mechanism by means of high-speed pneumatic cylinders

The blanks aligned by the chains are then conveyed from the suction belts to the delivery. The blanks are lying on the suction belts without guide bars only held by a vacuum. Each machine is equipped with 2 suction tables (one table for each lane) each with one transport belt.

Gluing unit

- Single roller glue unit with doctor blade and side limiters

- Glue unit and glue roller in non-corrosive execution

- Glue unit to be withdrawn sideways from machine

- Complete coverage against glue slings

- Position ensure optimum access to chain section and suction belts

A single roller upper glue unit with doctor blade ensures an even application of glue on the stereo cylinder. Side scrapers make it possible to top up only the areas where the glue is required. The required amount flows automatically out of glue bottles. The upper glue unit can be moved sideways out of the machine on easy running guides for cleaning purposes which means substantially reduced set-up times. Positioning the upper glue unit above the stereo cylinder in connection with splashguards prevents soiling of the machine or the blanks with glue during production. If one or more blanks are missing on the suction table below the stereo cylinder is lowered automatically, to prevent glue contaminating on the suction belts.

The stereo cylinder is divided in the middle for dual lane operation. The glue application stereos can be prepared outside the machine and then clamped to the stereo cylinder. When a job is finished the mounted stereo can be stored for repeat orders.

1up or 2up operation

- Pre-selection of the mode via touch screen panel

Setting the cycle depending on the carton length is via the input panel of the central input device. The direct drive then alter the speed of the knife cylinder automatically.

Delivery

- Delivery table can be disconnected from main machines

- Delivery belt speed synchronised with machine speed

- Delivery belt speed visible in the touch screen

A wide transport belt infinitively adjustable in height with variable take up rollers makes it possible to deliver even delicate blank shapes trouble free in a shingle arrangement. The gap of the shingle is infinitively variable by potentiometer. The delivery table can be moved away from the machine to facilitate access to the knife station and to ease the film change.

Pick and place station

- Servo driven placer arms

This station comprises out of a rotary placer with 4 arms and a positive driven magazine. The rotary arms are servo driven for easy and individual setting. The magazine can be set universal depending on the carton style. The motorised movement of the magazine ensures that the window material will be delivered to the pick up position. Part of the delivery will a missing film detector which also operates the compression roller after the window placement. In the input panel you can pre-select and store the following datas: film position to carton and positive movement of magazine.

Machine drive

- Maintenance-free toothed belt drive

The machine drive, beside the direct driven cylinders, is carried out by a maintenance-free toothed belt drive on the rear side of the machine. Tight tolerances in the positioning of the film are maintainable over a long period of time.

PLC Control

- Control of the machine by means of PLC and BUS technology

- Data input via touch screen panel

- All relevant datas can be seen on the screen

- Remote service possibility via telephone line (optional)

| Adjustment range, single stream operation | |||

|---|---|---|---|

| SimplyPick | |||

| min. | max. | ||

| Blank length | mm | 100 | 1020 |

| in | 3 15/16 | / | |

| Blank width | mm | 80 | 1120 |

| in | 3 1/8 | / | |

| Film Length | mm | 80 | 480 |

| in | 2 3/8 | / | |

| Film width | mm | 80 | 300 |

| in | / | / | |

| Power | |||

|---|---|---|---|

| Total power consumption | 20-25 kW | ||

| Adjustment range, double stream operation | ||

|---|---|---|

| SimplyPick | ||

| Blank width | mm | 545 |

| in | / | |

| Film width | depending on blank position | |

| Film thickness | 200 - 350 microns | |

| Output figures | ||

|---|---|---|

| when using belt lifter system | 1-stream max. pcs/ |

2-stream max. pcs/h |

| 1-up operation, blanks over 475 mm |

5000 | 10000 |

| 2-up operation, blanks over 475 mm |

10000 | 20000 |

Applications

Examples of Kohmann Window Patching Machine Applications

The following examples are simple illustrations of typical applications.

Please call or e-mail for information pertaining to your specific needs.

Gallery

Request more information

Fore more information, specifications or o get quote, please fill in this form and we'll get back on you as soon as possible. Thank you.

603-490-4392 mobile

603-635-1316 voice

603-635-7139 fax

bbarraclough@canampackaging.com

Can-Am Packaging Equip. Corp.

PO Box 191

30 Pulpit Rock Road

Pelham NH 03076 USA

further used equipment in category Kohmann Window Machines

Kohmann 1440 Window Machine

Kohmann has pushed the envelope with the new servo-driven, computer controlled window patching, pick and place and lining machine. The Kohmann GIANT Series has features from fee......learn more

Kohmann 1100 Window Machine

The Universal F1100 Window Machine from Kohmann is simple to operate, yet meets high production requirements. Based on years of experience manufacturing window machines which ha......learn more

Kohmann SpeedPlacer

Addon Speed Placerfor window patching and lining machinesmodels F-1100 Universal and F-1440 Servo......learn more

Kohmann Punch & Score

Kohmann GmbH engineered the first Punch and Score Units for panoramic window production in 1985. The Kohmann Punch and Score Unit is designed for 24/7 operation and produces hig......learn more

Kohmann PrintChecker 450

Innovative By means of the print inspection machine you are able to check the surface of folding cartons and other print media. Differences in colours, printing and in ......learn more

Kohmann PrintChecker 600

Innovative By means of the print inspection machine you are able to check the surface of folding cartons and other print media. Differences in colours, printing and in ......learn more

Kohmann EasiPlace

The Easi-Place machine has been designed to combine DVD/CD trays with their backing folders, placing up to six trays in one operation. The unit is comprised of a cast iron frame......learn more

Kohmann Starlet 620 Folder Gluers

Key Features Ideal for processing straight line boxes, crash lock bottom boxes, double wall boxes and CD/DVD sleeves Low spac......learn more