Used Equipment

Used equipment: Blanker, Die Cutter, Cutting Shear, Folder Gluer, Foil Stamper, Laminator, Miscellaneous - Jagenberg Pre Feeders and Graphic West Pack Pack Stations and Nordson Units, Printing Press, Window Machine

Blanker

Bobst SP-142 ER-A

Year: 1982

Used 1982 Bobst SP-142 ER-A Die Cutter Blanker...learn more

Reference #: Bobst SP-142 ER-A

Bobst SP-142 ER-A Year: 2000. 56" width, OEM maximum rated machine speed: 108 Strokes/Minute, Last 3 months GROSS avg speed (run hours only): 47 Strokes/Minute.

Bobst SP-142 ER-B

Year: 1980

Used 1980 Bobst SP-142 ER-B Blanker Die Cutter...learn more

Reference #: Bobst SP-142 ER-B

Bobst SP-142 ER-B. Year: 2000. 56" Width. OEM maximum rated machine speed: 108 Strokes/Minute, Last 3 months GROSS avg speed (run hours only): 37 Strokes/Minute

Bobst SP - ER 130

Year: 1986

Used 1986 Bobst SP - ER 130 Blanker Die Cutter...learn more

Reference #: Bobst SP - ER 130

Bobst SP - ER 130. Year: 2011. Full centerline/ quicklock system, 50" width. OEM maximum rated machine speed: 117 Strokes/Minute. Last 3 months GROSS avg speed (run hours only): 71 Strokes/Minute

Die Cutter

Iberica Die Cutter

One (1) Automatic Platen Press Iberica SRK -144 2004 with Blanking Unit 104 CM x 144 CM...learn more

Reference #: Iberica Die Cutter

One (1) Automatic Platen Press Iberica SRK -144 2004 with Blanking Unit 104 CM x 144 CM

Cutting Shear

Schneider Werk Knife Cutting Shear

Year: 1968

Used 1968 Schneider Werk Knife Cutting Shear...learn more

Reference #: Schneider Werk Knife Cutting Shear

Schneider Werk Knife Cutting Shear. Year equipment Manufactured: 1968. 52" width. Voltage: 380/220

Folder Gluer

Bobst Domino 90/A-1 Straight Line

SN 033207203 1998 GSSE and sleeves Linear ejector 900 mm maximum carton 126 mm minimum (31.5 x 35.5) Straight Line boxes Automatic Feed Pressing belt delivery Standard equipment Straight line gluing Bobst Carton Pack II...learn more

Reference #: Bobst Domino 90/A-1 Straight Line

SN 033207203

1998

GSSE and sleeves

Linear ejector

900 mm maximum carton 126 mm minimum (31.5 x 35.5)

Straight Line boxes

Automatic Feed

Pressing belt delivery

Standard equipment

Straight line gluing

Bobst Carton Pack II

Bobst Domino 110 -MII Matic Straight Line Only

1994 Max Width 1100 Min Width 126 mm Max Length 800 mm Min Length 60 mm Max Speed 20-400 m/minute Mod. Domino 110 -II Matic Straight-line HHS Detection Extrusion System with Ejector Ergo Pack Station at End for Cases Pre Fold and Final Fold Parts Needed...learn more

Reference #: Bobst Domino 110 -MII

1994

Max Width 1100

Min Width 126 mm

Max Length 800 mm

Min Length 60 mm

Max Speed 20-400 m/minute

Mod. Domino 110 -II Matic

Straight-line

HHS Detection Extrusion System with Ejector

Ergo Pack Station at End for Cases

Pre Fold and Final Fold Parts Needed

Jagenberg Diana 105-2

Year: 1987

max. 1050 mm, min. 50 mm, straight line, lock bottom, double wall,4 + 6 point gluing, electronic upper gluing system KAS, 6 channels with 4 guns, lower discgluing system left, vibrator / blowing air at feeder, pre breaker right and left, kicker, counter,digital read out unit, timed aligning chain, additional middle transport in folding, motorized tuckin station, controlled press station, additional conveyor. Reconditioning 2019: cleaned, checked,repainted, new feeder- and transport belts, as well as new press belts...learn more

Reference #: Jagenberg Diana 105-2

max. 1050 mm, min. 50 mm, straight line, lock bottom, double wall, 4 + 6 point gluing, electronic upper gluing system KAS, 6 channels with 4 guns, lower disc

gluing system left, vibrator / blowing air at feeder, pre breaker right and left, kicker, counter, digital read out unit, timed aligning chain, additional middle transport in folding, motorized tuck in station, controlled press station, additional conveyor. Reconditioning 2019: cleaned, checked, repainted, new feeder- and transport belts, as well as new press belts.

Bobst Domino 110 M II

Year: 1997

max. 1100 mm, min. 126 mm, straight line, lock bottom, double wall, 4+ 6 point gluing, electronic upper gluing system HHS X-tend with 3 guns, lower disc gluingsystem left, electronic back folding via servos, vibrator at feeder, tooth gauge at feeder, prebreaker right and left, kicker, counter, motorized lower transfer station, squaring device intransfer station, squaring station at press station, motorized format adjustment, pneumatic,controlled press station. Reconditioning 2019: cleaned, checked, repainted, new feeder- andtransport belts, as well as new press belts, new main drive motor and new drive for presssection...learn more

Reference #: Bobst Domino 110 M II

max. 1100 mm, min. 126 mm, straight line, lock bottom, double wall, 4 + 6 point gluing, electronic upper gluing system HHS X-tend with 3 guns, lower disc gluing system left, electronic back folding via servos, vibrator at feeder, tooth gauge at feeder, pre breaker right and left, kicker, counter, motorized lower transfer station, squaring device in transfer station, squaring station at press station, motorized format adjustment, pneumatic, controlled press station. Reconditioning 2019: cleaned, checked, repainted, new feeder- and transport belts, as well as new press belts, new main drive motor and new drive for press

section.

Jagenberg Diana 104-1

Year: 1998

max. 1040 mm, min. 50 mm, straight line, lock bottom, 4 + 6 pointgluing, electronic upper gluing system KAS, 8 channels with 4 guns, high pressure, lower discgluing system left, electronic back folding with servos, vibrator, feeder with own servo drive, prebreaker right and left, kicker, counter, digital read out unit, module 150, motorized middletransport in folding, Jagenberg DBS01 control, motorized transfer station, fully automatic formatadjustment Jagset II, pneumatic press station. Reconditioning 2019: cleaned, checked,repainted, new feeder- and transport belts....learn more

Reference #: Jagenberg Diana 104-1

max. 1040 mm, min. 50 mm, straight line, lock bottom, 4 + 6 point gluing, electronic upper gluing system KAS, 8 channels with 4 guns, high pressure, lower disc gluing system left, electronic back folding with servos, vibrator, feeder with own servo drive, pre breaker right and left, kicker, counter, digital read out unit, module 150, motorized middle transport in folding, Jagenberg DBS01 control, motorized transfer station, fully automatic format adjustment Jagset II, pneumatic press station. Reconditioning 2019: cleaned, checked,repainted, new feeder- and transport belts.

Bobst Domino 85 M

Year: 1984

max. 850 mm, min. 126 mm, straight line, lock bottom, double wall, 4point gluing, electronic upper gluing system with 2 guns, lower disc gluing system left,mechanical back folding, vibrator & tooth gauge at feeder, pre breaker right and left, kicker,counter, additional middle transport in pre breaker, squaring chain, additional middle transportin folding, pneumatic, controlled press station. Reconditioning 2019: cleaned, checked,repainted, new feeder- and transport belts...learn more

Reference #: Bobst Domino 85 M

max. 850 mm, min. 126 mm, straight line, lock bottom, double wall, 4 point gluing, electronic upper gluing system with 2 guns, lower disc gluing system left,

mechanical back folding, vibrator & tooth gauge at feeder, pre breaker right and left, kicker, counter, additional middle transport in pre breaker, squaring chain, additional middle transport in folding, pneumatic, controlled press station. Reconditioning 2019: cleaned, checked,repainted, new feeder- and transport belts.

Bobst Domino 110 M II

Year: 1993

max. 1100 mm, min. 126 mm, straight line, lock bottom, double wall, 4point gluing, electronic upper gluing system HHS C-1100, 16 channels with 4 guns, lower discgluing system left, vibrator at feeder, tooth gauge at feeder, pre breaker right and left, kicker,counter, digital readout unit, lower transfer station motorized adjustable, pneumatic, controlledpress station. Reconditioning 2019: cleaned, checked, repainted, new feeder- and transportbelts, as well as new press belts...learn more

Reference #: Bobst Domino 110 M II

max. 1100 mm, min. 126 mm, straight line, lock bottom, double wall, 4 point gluing, electronic upper gluing system HHS C-1100, 16 channels with 4 guns, lower disc gluing system left, vibrator at feeder, tooth gauge at feeder, pre breaker right and left, kicker, counter, digital readout unit, lower transfer station motorized adjustable, pneumatic, controlled press station. Reconditioning 2019: cleaned, checked, repainted, new feeder- and transport belts, as well as new press belts.

Bobst Domino 110 M II

Year: 1995

Bobst Domino 110 M II, max. 1100 mm, min. 126 mm, straight line, lock bottom, 4 + 6 point gluing, electronic upper gluing system HHS X-tend, 8 channels with 4 guns, high pressure, lower disc gluing system left, electronic back folding via servos, vibrator at feeder, cliche gluing system, nick breaker, pre breaker right and left, kicker, counter, digital read out unit, motorized transfer station, pneumatic, controlled press station. Reconditioning 2018: cleaned, checked, repainted, new feeder- and transport belts, as well as new press belts. ...learn more

Reference #: Bobst Domino 110 M II 1995

Bobst Domino 110 M II, max. 1100 mm, min. 126 mm, straight line, lock bottom, 4 + 6 point gluing, electronic upper gluing system HHS X-tend, 8 channels with 4 guns, high pressure, lower disc gluing system left, electronic back folding via servos, vibrator at feeder, cliche gluing system, nick breaker, pre breaker right and left, kicker, counter, digital read out unit, motorized transfer station, pneumatic, controlled press station. Reconditioning 2018: cleaned, checked, repainted, new feeder- and transport belts, as well as new press belts.

Bobst Media 100 II

Year: 2002

Bobst Media 100 II Year: 2002 For Production of Straight Line Crash Lock Cartons & 4 & 6 Corner CartonsCarton Sizes:Maximum Width 1000 mm Minimum Width 56 mmMaximum Length 600 mm Minimum Length 60 mmConvertible stock Solid 100-600 g/m2Corrugated up to E flute Maximum Thickness 8 mmOperating speed 20 - 300 m/minDrive System Inching speed 20 m/min Vibrator on feederPre fold sectionKurandt CB CL50 Bar Code ReaderServo Driven 4 & 6 Corner systemBobst Computer SettingHHS Xtrend Electronic Hot Melt Glue System with 2 Guns & 2 ULT 100 Glue line detectors4 Litre & 25 Litre Hot Melt TanksHHS C110 Electronic Glue System with 4 GunsGlue PumpLongford Insertor CD’s/wallets Etc With Kurandt Position MonitorSide Glue TankTrombone SectionKickerKurandt Carton EjectorElectronic CounterCompression Conyevor Machine Dimensions:Length 12500 - 11800 mm, Width 1920 - 2300 mm, Height 2650 mm, Weight 5700 kg...learn more

Reference #: Bobst Media 100 II

For Production of Straight Line Crash Lock Cartons & 4 & 6 Corner Cartons

Carton Sizes:

Maximum Width 1000 mm Minimum Width 56 mm

Maximum Length 600 mm Minimum Length 60 mm

Convertible stock Solid 100-600 g/m2

Corrugated up to E flute Maximum Thickness 8 mm

Operating speed 20 - 300 m/min

Drive System Inching speed 20 m/min

Vibrator on feeder

Pre fold section

Kurandt CB CL50 Bar Code Reader

Servo Driven 4 & 6 Corner system

Bobst Computer Setting

HHS Xtrend Electronic Hot Melt Glue System with 2 Guns

& 2 ULT 100 Glue line detectors

4 Litre & 25 Litre Hot Melt Tanks

HHS C110 Electronic Glue System with 4 Guns

Glue Pump

Longford Insertor CD’s/wallets Etc With Kurandt Position Monitor

Side Glue Tank

Trombone Section

Kicker

Kurandt Carton Ejector

Electronic Counter

Compression Conyevor

Machine Dimensions:

Length 12500 - 11800 mm, Width 1920 - 2300 mm, Height 2650 mm, Weight 5700 kg

Bobst Domino 90 - A3

Year: 1995

Bobst Domino 90 - A3, max. 900mm, min. 45mm, straight line, lock bottom, 4 point gluing, new electronic upper gluing system with 2 guns, lower disc gluing system left, electronic back folding, pre breaker right and left, kicker,counter, digital readout unit, motorized transfer station, additional middle transport in folding station, controlled press station. Reconditioning 2016: cleaned, checked, repainted, new feeder- and transport belts, as well as new press belts....learn more

Reference #: Bobst Domino 90 - A3

Bobst Domino 90 - A3, max. 900mm, min. 45mm, straight line, lock bottom, 4 point gluing, new electronic upper gluing system with 2 guns, lower disc gluing system left, electronic back folding, pre breaker right and left, kicker,counter, digital readout unit, motorized transfer station, additional middle transport in folding station, controlled press station. Reconditioning 2016: cleaned, checked, repainted, new feeder- and transport belts, as well as new press belts.

Post 30

Year: 1983

Used 1983 Bobst Whistler 760 Straight Line Folder Gluer $10,000.USD...learn more

Reference #: Post Whistler 760

Bobst Whistler 760. Year: 1983. OEM maximum rated machine speed: Not Used. Unit of Measure: Belt speed (feet/minute), Last 3 months GROSS avg speed (run hours only): Not Used Cartons/Hour. Straight Line

Foil Stamper

Bobst BMA126 - Hotfoil Stamping Machine

Year: 1989

maxi size : 920 x 1260 mm, with 3 hotfoil advances. Condition: As is – in good running condition, in production, available immediately...learn more

Reference #: Bobst BMA126

- maxi size : 920 x 1260 mm

- with 3 hotfoil advances

Condition:

- As is – in good running condition

- in production

- available immediately

Laminator

Bobst Media 100

Year: 2008

Used Bobst Media 100, 2008, Nice condition, Under power, Ran only one shift since purchased,not every day, 4 corner, Backfold...learn more

Reference #: Bobst Media 100

2008 Bobst Media 100

- Nice condition

- Under power

- Ran only one shift since purchased (not every day)

- 4 corner

- Backfold

Miscellaneous - Jagenberg Pre Feeders and Graphic West Pack Pack Stations and Nordson Units

Packer /Nordson units/Prefeeders

Packer is Graphic West. 2018 Jagenberg Pre Feeders Nordson Units -Integrated hot melt/Cold glue system with full detection controls -10 units...learn more

Reference #: Packer /Nordson units/Prefeeders

Packer is Graphic West. 2018

Jagenberg Pre Feeders

Nordson Units -Integrated hot melt/Cold glue system with full detection controls -10 units

Printing Press

2004 KBA Rapida 105

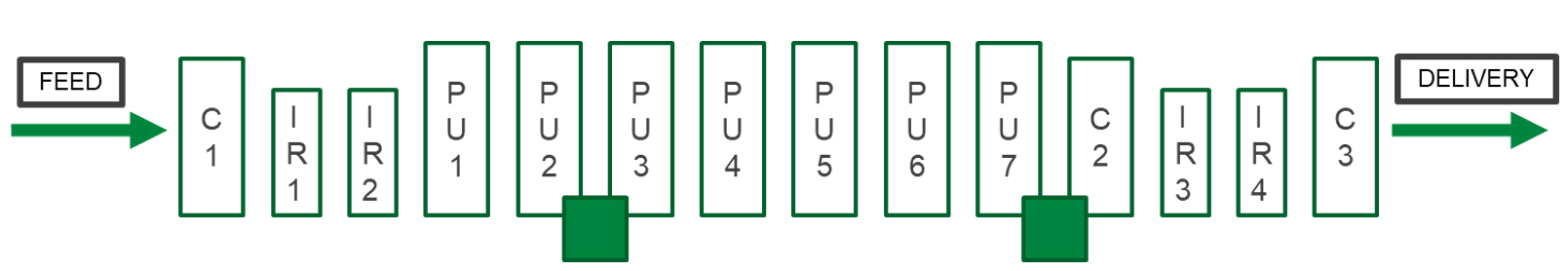

14 Station Press – 7 print units, 3 coaters, 4 stub dryers Inter-deck UV lights after Print Units 2 and 7 Conventional and UV capabilities 11,000 sph dial speed ...learn more

Reference #: 364528

- Serial #364528

- 14 Station Press – 7 print units, 3 coaters, 4 stub dryers

- Inter-deck UV lights after Print Units 2 and 7

- Conventional and UV capabilities

- 11,000 sph dial speed

- Installed and running in current location since 2016

- Press underwent repairs in 2020 after an air pan traveled through units 10+11.

- All affected gears were realigned and pinned by Koenig and Bauer technicians

- Coating unit #2 was re-paralleled

- Print tests were completed and press is a capable of running 7 color products again

KBA Varimat 126

Year: 1995

1995 KBA Varimat 126 Press...learn more

Reference #: KBA Varimat 126

KBA Varimat 126, Year: 1995, 50" width, OEM maximum rated machine speed: 10,000 Sheets/Hour, Last 3 months GROSS avg speed (run hours only): 6,000 Sheets/Hour.

KBA Rapida 104

Year: 1993

Used 1993 KBA Rapida 104 Press...learn more

Reference #: KBA Rapida 104

KBA Rapida 104 Year: 1993. 40" width, OEM maximum rated machine speed: 14,000 Sheets/Hour, Last 3 months GROSS avg speed (run hours only): 7,436 Sheets/Hour.

Window Machine

Kohmann 1350 Window Machine

Year: 1989

Automatic Window Patcher Two Stream Chain Transport System Retractable Glue System Vacuum Belt Transfer Auto acetate cut off control Belt delivery table Max carton blank width : 1330 mm, Min carton blank width : 80 mm, Max window size : 720 x 980 mm Min window sise : 50 x 30mm Max speed : 1050 p/min Max caliper : All grades up to B flute Windowing material : All types...learn more

Reference #: Kohmann 1350 Window Machine

Automatic Window Patcher

Two Stream

Chain Transport System

Retractable Glue System

Vacuum Belt Transfer

Auto acetate cut off control

Belt delivery table

Max carton blank width : 1330 mm,

Min carton blank width : 80 mm,

Max window size : 720 x 980 mm

Min window sise : 50 x 30mm

Max speed : 1050 p/min

Max caliper : All grades up to B flute

Windowing material : All types

Kohmann 1120 Window Machine

Year: 2008

Two Stream Capability Suction Feed Touch Screen Computer Control Automatic set up via touch screen Servo Motors Driven film Cut Off There is no Delivery Table however a Table can be supplied...learn more

Reference #: Kohmann 1120 Window Machine

Two Stream Capability

Suction Feed

Touch Screen Computer Control

Automatic set up via touch screen

Servo Motors Driven film Cut Off

There is no Delivery Table however a Table can be supplied

Technical data:

Maximum Blank Length: 1240mm

Minimum Blank Length: 100mm

Maximum Blank width: 1120mm

Minimum Blank width: 80mm

Maximum Film Length: 800mm

Minimum Film Length: 60mm

Maximum Film Width: 840mm

Minimum Film Width: 30mm

Kohmann F1050 /2

Year: 1996

Two Stream, Rotary Feed Chain Station Film Coating unit Delivery Belt Max blank length 1020 mm Min blank length 100 mm Max blank width 505 mm Min blank width 80 mm Max film length 720 mm Min film length 50 mm Max film width 840 mm Min film width 30 mm...learn more

Reference #: Kohmann F1050 /2

Two Stream,

Rotary Feed

Chain Station

Film Coating unit

Delivery Belt

Max blank length 1020 mm

Min blank length 100 mm

Max blank width 505 mm

Min blank width 80 mm

Max film length 720 mm

Min film length 50 mm

Max film width 840 mm

Min film width 30 mm

Heiber & Schröder Window Patcher

Year: 2002

High Speed line consisting of: Window Patcher WP 1100/3 M, max. size 1100 mm, 2-stream, feeder with vacuum, servo drive & cleaning guns, digital read out units, paper and solid board from 250 g/m² up to 800 g/m², F, E- and B-flute up to 5 mm thickness. Automatic roll changer, max. size 1100 mm, 3-stream, servo drive Fully automatic jogger stacker, year 2002 max. size 1400 mm, 3-stream, conveyor band. Reconditioning 2019: cleaned, checked, partial repainted....learn more

Reference #: Heiber & Schröder Window Patcher

High Speed line consisting of:

Window Patcher WP 1100/3 M, max. size 1100 mm, 2-stream, feeder with vacuum, servo drive & cleaning guns, digital read out units, paper and solid board from 250 g/m² up to 800 g/m², F, E- and B-flute up to 5 mm thickness.

Automatic roll changer, max. size 1100 mm, 3-stream, servo drive

Fully automatic jogger stacker, year 2002 max. size 1400 mm, 3-stream, conveyor band.

Reconditioning 2019: cleaned, checked, partial repainted.

Kohmann 1100

Year: 2004

Timed belt feeder Automatic suction air on feeder Control system for missing film and carton Jam detector at delivery Two Up Operation Single Lane...learn more

Reference #: Kohmann 1100

Timed belt feeder

Automatic suction air on feeder

Control system for missing film and carton

Jam detector at delivery

Two Up Operation Single Lane

Kohmann 1100 43" Window Patcher

Year: 2012

40" Vacuum Cylinder, Vacuum Assist Bottom Belt feed with Timed Nylon Lifters, Register Chain that Transfers to a Vacuum Belt, Dual Independently Controlled Trip Mechanisms for Missing Blanks, Servo Driven Film Feed, Servo Driven Film Cut Off, New Style Glue System with Doctor Blade Metering Unit (No Pan-Easy Clean Up) Nylon Dams to Control Location of Glue, Make Ready Table, Pre-Set Counter, All Cog Tooth Belt Drive System (Less Maintenance, Less Noise), Completely Guarded with Interlocks on Doors, All P.L.C. Controls, Two (2) Standard Unwind Shafts for Two (2) Streams...learn more

Reference #: Kohmann 1100 43 Window Patcher

40" Vacuum Cylinder, Vacuum Assist Bottom Belt feed with Timed Nylon Lifters, Register Chain that Transfers to a Vacuum Belt, Dual Independently Controlled Trip Mechanisms for Missing Blanks, Servo Driven Film Feed, Servo Driven Film Cut Off, New Style Glue System with Doctor Blade Metering Unit (No Pan-Easy Clean Up) Nylon Dams to Control Location of Glue, Make Ready Table, Pre-Set Counter, All Cog Tooth Belt Drive System (Less Maintenance, Less Noise), Completely Guarded with Interlocks on Doors, All P.L.C. Controls, Two (2) Standard Unwind Shafts for Two (2) Streams